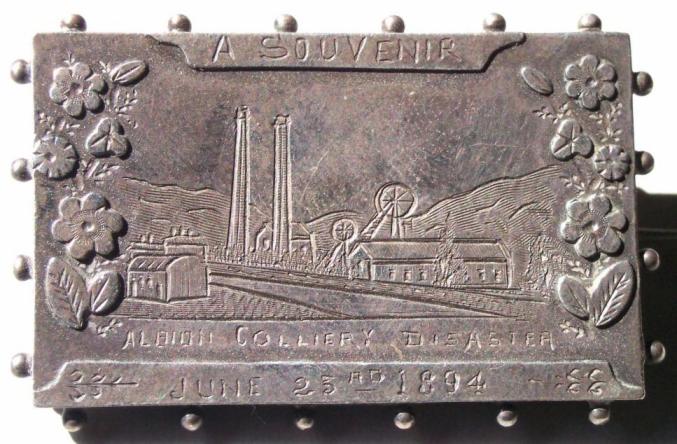

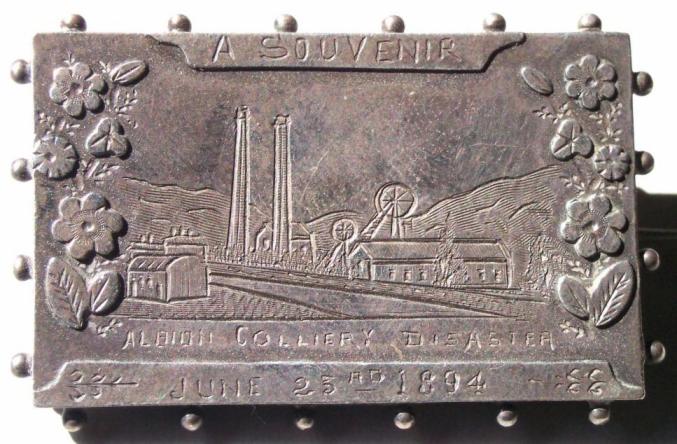

A souvenir of the Albion Colliery Disaster of 1894.

Souvenir Brooch - engraved "Albion Colliery Disaster, June 25th 1894".

Can anyone tell me anything about the above brooch? It is has a locket type recess on the reverse and is made of hollow pressed (?) and hall marked silver with a large brass pin across its full width. The flan of the brooch is most likely a mass produced blank standard it bears Birmingham silver marks for 1893, a full year before its obverse could possibly have been engraved. There is a small rectangular stamped makers mark on the reverse also but the first letter is worn away and only the abbreviation "BROS" remains. The brooch measures 41 mm by 26 mm. I assume this item was made to raise funds for a disaster appeal that may have been set up after the disaster.

Any answers or further information about the above item would be greatly appreciated. Also has anyone any further information about the colliery disaster itself or can they advise on the missing initial(s) which make up the makers mark described.

Submitted By :

Glyn Howell.

Date: May 2005.

REPLY No.1

A large number of items were made like this one to raise funds for Welsh mining disasters plus certain industrial disputes.

I have checked our listings at Big Pit Museum and found a brooch of exactly

the same design but in gold. Pontypridd Museum has something similar as well

in silver (?) but I am waiting for them to confirm this. It seems that a

number of these brooches were produced in various precious metals to raise

funds for the dependants of the victims of the disaster. We haven't got a

photo of our brooch but could do so if needed, however the design appears to

be identical to the one illustrated. I will contact Pontypridd Museum (the

nearest museum to the former Albion Colliery in Cilfynydd) to see if they have

any further information.

Submitted By : Ceri Thompson (Big Pit - National Mining

Museum for Wales)

Date: May 2005.

REPLY No.1

I have recently seen a similar silver brooch with exactly the same engraved design for this disaster but which was oval in shape. It was about the same size as the one described above.

The following details about the explosion are taken from the Rhondda Cynon Taf Libraries Heritage Trail Website .

Albion Colliery - Cilfynydd, South Wales.

"Sinking of Albion

Colliery began in 1884 on the site of Ynyscaedudwg Farm. It was owned by the

Albion Steam Coal

Company and opened in August 1887. Production

at the colliery quickly flourished and it's average weekly output soon reached

12,000 tons. This was the largest tonnage for a single shaft coal-winding

colliery in the whole of South Wales. By 1893, 1,500 men and boys were

employed at the Albion. The colliery's early years were relatively free of

serious incidents but disaster struck on the afternoon of Saturday June 23rd

1894. On

that fateful afternoon the night shift was at work removing dust and repairing

the roadways. At 3.50 p.m. two loud reports were heard above ground in quick

succession. These were followed immediately by a charge of dust and smoke from

the downcast shaft and then from the upcast shaft. The effects of the

explosion were appalling. It caused the deaths of 290 men and boys, the worst

mining disaster in South Wales to that date and only to be surpassed by the

explosion at the Universal Colliery, Senghenydd in 1913. Few miners were

brought out alive and the majority of them subsequently died of their

injuries. Victims' bodies were taken to the hayloft of the pit's stables that

acted as a temporary morgue and harrowing scenes of relatives looking for

their family members by lantern light followed. Many of the bodies were badly

mutilated and at least three of them taken from the hayloft had to be returned

after being mistakenly identified. Another source of confusion was that nobody

knew the number of men below ground when the explosion occurred.

An inquest was held at Pontypridd the following month. It immediately became

apparent that there was a difference of opinion as to the cause and location

of the explosion between the inspectors and professional witnesses on the one

hand and the colliery owners on the other. Having heard the evidence the jury

members concluded that an explosion of gas was accelerated by coal dust but

they failed to reach agreement on other issues. The Government appointed a

barrister Mr. J. Roskill to scrutinise the evidence. His report was presented

to the Home Secretary in September 1894. Mr. Roskill was of the opinion that

the explosion was caused by the blasting of timbers which ignited an

accumulation of gas and that in turn ignited the coal dust. The likelihood of

this happening had increased because of dangerous and sloppy working practices

at the colliery. These included the blasting of timbers during shifts,

inadequate watering of the mine to lay dust and new Saturday shift patterns

that meant there was no interval for clearing dust between shifts. Although

the report recommended prosecuting the Albion Coal Company and various

individuals, in the event proceedings were taken only against Phillip Jones,

the manager and William Anstes, the chargeman, and fines of £10 and £2 were

imposed respectively.

The colliery was reopened within two weeks of the explosion and it wasn't long

before the miners lost in the disaster were replaced. The workforce grew to

1,735 by 1896, increasing to 2,589 by 1908. The following years saw a constant

decline in the numbers of men employed at the pit and in 1928, the Albion

Steam Coal Company went into liquidation. The Powell Dyffryn Steam Coal

Company purchased its assets and it remained their property until the

formation of the National Coal Board in 1947 at which time the workforce was

just under 1000. By the time the colliery closed in 1966 the numbers had

almost halved. After Albion Colliery had ceased to provide work for

Cilfynydd's inhabitants the tips still towered menacingly over the village

threatening a disaster similar to Aberfan. A two-phased scheme to reduce the

steep gradient of the colliery spoil began in 1974 and was completed two years

later."

Submitted By : Mark Smith.

Date: May 2005.