What's does the embossed number "15" stand for on certain N.C.B. Explosive Canisters Identification Tags?

Two explosives canister identification tags from Staffordshire both with an embossed number "15" on them- Lea Hall, Cannock Chase and Norton, Stoke-on-Trent.

The image above is of two explosive canister identification tallies or tags. I'm sure many collectors will have come across such checks before. They are very distinctive in that they are always of brass, are uniface and of 43 mm diameter plus have two pierced holes orientated as shown. These holes were used for riveting the tags onto the top of the lids of the N.C.B.'s standard design of 5 lb. capacity explosive carrying canister. Such canisters were tagged with numbered tallies as a form of identification and probably as a means of controlling their issue and return to and from the pit's magazine. I have seen such tokens form many Yorkshire, Staffordshire, Co. Durham and Welsh pits.

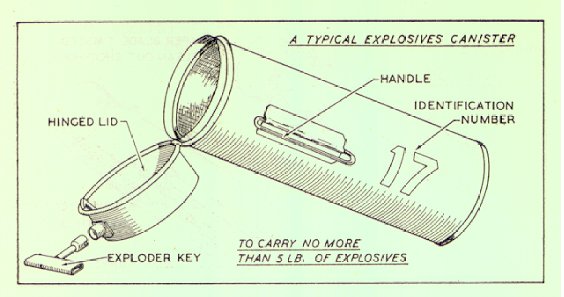

An sketch of a typical 5 lb Explosives Carrying Canister taken from a 1950s N.C.B. shot firing manual

During the NMMA's first field trip to Big Pit Colliery Museum in Wales a group of us found two such canisters on the spoil tip of the now abandoned private drift mine site of Cwm Glo (see A.J. Booth's book "Small Mines of South Wales", Vol. I, pages 24-25). One of these canister, post cleaning, is shown below.

A standard sized (22 cm dia. by 27 cm tall) Explosives Carrying Canister found at Cwm Glo Drift Mine, South Wales - Note the brass identification tag (numbered "559") still in-place on the canister's lid.

Both the canisters found that day still had their brass identification tallies attached and were constructed to conform to what appears to be the N.C.B.'s standard design for such boxes. The bodies of both canisters were formed from multiple plied canvas/rubber conveyor belting material and they each had a similar metal lid lock (which can only be opened with a shot firer's brass safety key). Each canister also had a carrying handle and strap complete with a buckle fastener. Both of the Cwm Glo examples probably originated from Big Pit and only found their way to down the valley at a later date in their working lives.

Many of the explosive canister tags I have seen simply carry hand stamped identification numbers on them. However, others do carry the name of their respective pit of origin, often hand or occasionally machine stamped into their fabric. The two illustrated examples above are from two of three pits known to me (the other being West Cannock No.5) which used embossed tally/tag designs. All three of these examples from Staffordshire contain the embossed number "15" in their legends. I believe that this number signifies that the 5 lb. capacity canister, to which they were originally attached, were suitable only for holding up to "15" sticks of explosives. Can anyone confirm this or give me an alternative answer to this mystery? I'm sure a retired N.C.B. shot firer could tell us the answer to this enigma.

(i) At N.C.B. collieries there are two standard diameters of cartridges: 1 1/4 in. and 1 7/8 in., both inclusive of sheath, if any. In general, cartridges of very small diameter are less satisfactory than larger ones, and diameters less than 11/4 in. are not recommended.